(1) Introduction

The filter bottle/filter housing can generally be categorised into two styles. One style involves the filter material being directly filled into the filter housing for use, while the other is used in conjunction with a filter element for filtration. Generally speaking, the selection of filter bottles is primarily based on the specifications for the incoming and outgoing water and is divided into 2-point, 4-point, 6-point configurations, etc., as well as the material and size of the filter housing. Therefore, this article specifically compiles a list of manufacturers of filter bottles (filter housings) in Taiwan as an important reference for your selection of filter bottles (filter housings).

It is well known that the filter is the core component of the water purifier. However, the filter bottle (filter housing) plays the most crucial role in protecting the filter, a fact that is often overlooked.

The quality of the filter bottle (filter housing) directly impacts whether the water purifier will leak or burst.

The filter bottle is a device designed for the installation of the filter core and is one of the essential accessories of the water purifier.

There is no filter cartridge that cannot filter; however, when individuals choose water purifiers, they often focus solely on the function of the filter core, the appearance of the water purifier, and cost considerations. The filter bottle, which is frequently forgotten, is actually one of the many components of the water purifier and plays a very important role and function.

A filter housing can rupture due to the impact of water pressure, leading to water leakage, and it may burst instantly if it cannot withstand excessive water pressure.

The water pressure in our living environment can also affect the magnitude of water hammer, influenced by the floor we reside on and the differences between day and night, posing a significant threat to the filter bottle. The most common issue is that the filter bottle bursts and leaks. Therefore, special attention should be paid to the following points:

- Durability of the filter bottle

- O-ring tightness and the burst pressure rating of the filter bottle

- Whether the design of the inlet and outlet holes of the inner threads can withstand the pressure exerted by the tube fittings without breaking

- The hydrophilicity, weather resistance, and impact resistance of the filter bottle material.

(2) What are the benefits to the water purifier factory?

Did you know that in our daily lives, most of the branded products we encounter are actually produced by OEM (Original Equipment Manufacturer)? A factory possesses its own specialised technology, which, when combined with the brand advantage of the brand owner, allows both to complement each other, achieving a win-win situation.

Therefore, it is crucial to carefully select a qualified manufacturer. By adopting a division of labour model, the factory only needs to focus on improving product quality, production capacity, and technical expertise, while the brand owner does not need to invest in additional production equipment costs. Entrusting manufacturing to a professional factory can also significantly reduce costs, shorten the time to market for new products, and maximise the added value of the brand to ensure optimal profits.

(3) What are the selection criteria?

The following outlines the conditions for selecting OEM/ODM manufacturers of water purifiers:

1.Does the factory have international certification?Certifications such as ISO9001 and ISO14001 would be preferable. (Refer to Note 1)ISO certification bodies are authoritative organisations recognised by the state, known for their rigorous and prudent auditing of the quality and environmental systems of enterprises.For the internal management of the enterprise, quality and environmental management can be conducted in accordance with the strictly audited international standardisation processes, thereby strengthening the internal management levels within the company. Implementing the international ISO9001 quality management system can not only enhance product quality but also enable enterprises to improve their advantages in various areas of product quality when competing with others. By applying for international product certification, companies can ensure compliance with regulations regarding product design and production processes, utilising materials that do not harm human health or cause environmental pollution.

Note 1: The International Organization for Standardization was established on 23 February 1947. It is an international standard-setting body that formulates international standards for industry and commerce globally.ISO is headquartered in Geneva, Switzerland, and currently has 164 member states. The organisation is classified as a non-governmental organisation, and its official languages are English, French, and Russian. Participants include national standards bodies and major companies from each Member State. (For full details, please refer to Wikipedia)

2.Do you have export experience?

Buyers seeking OEM/ODM contract manufacturing for water purifiers will find it easier to communicate with you if you have export experience. Furthermore, the water purification industry employs many specific terminologies, making it advantageous for buyers to select a contract factory that is familiar with the export process. Additionally, different countries have varying specifications for water purifiers, meaning that experienced factories can provide solutions and reduce ineffective communication.

3.Have you established a laboratory, purchased product liability insurance, etc.?OEMs procure product liability insurance not only to reassure buyers but also to encourage them to strengthen their quality awareness and mitigate the risk of claims, thereby fostering a positive corporate image.Choosing a factory with a laboratory allows you to ascertain whether the factory places significant importance on product quality, and whether its laboratory verifies the reliability of each product according to the testing specifications of the National Sanitation Foundation (NSF).Moreover, it is essential to check whether the factory consistently implements the following quality control processes:

- IQC (Incoming Quality Control) inspection

- IPQC (In-Process Quality Control) inspection

- PQC (Process Quality Control) inspection of semi-finished products

- FQC (Final Quality Control) inspection

- OQC (Outgoing Quality Control) inspection

4.Does the factory accept OEM orders from buyers?

It is also important to evaluate whether the factory can customise exclusive products for the buyer. The factory must possess the capabilities for product design, manufacturing, assembly, quality control, etc., before it can be awarded the contract for OEM production. The factory can also assist the buyer with professional services such as design and development.To assess whether a factory has adequate capabilities, the following four items can be evaluated:

- Production equipment: automatic machinery, production lines, ultrasonic rotary melting machines, water test/air test machines, etc.

- Injection equipment: injection moulding machines (equipped with robotic arms), etc.

- Product testing equipment: 3D projectors, MI (Melt Index) plastic melt index detectors, specific gravity scales, microbial testing equipment, various water quality analysis instruments, etc.

- Custom development capability: The factory should not simply outsource but also possess design capabilities. It is crucial to understand the development trends in the water purification market to provide buyers with design and development in the correct product direction, helping them avoid missteps. By integrating buyer needs with technology, development costs can be reduced, allowing new products to be launched on schedule.

5.Does the factory have its own production line, and can it control delivery times and quality independently?

Only with an in-house production line can a factory guarantee precise delivery times, avoiding the frequent issue of being unable to provide a delivery timeframe. If the factory cannot respond to the buyer’s delivery date immediately, it will struggle to arrange shipping promptly—especially during the current epidemic, when shipping schedules and freight rates are generally unpredictable, making this aspect quite critical. Another key point is quality control. A visible production process allows customers to feel confident that no corners are being cut in product manufacturing and that recycled materials are not being mixed in, which could compromise product quality.

6.To qualify as a water purification equipment manufacturer, the factory must possess the following four major items:

- Complete and sophisticated production equipment

- Injection equipment (as approximately 80% of water purification equipment is made from plastic raw materials, the quality of key components is crucial; this can only be controlled and assured if the components are produced in-house, along with the assurance of timely delivery)

- Product testing equipment

- Custom development capabilities

(4) The common filter bottle specifications on the market

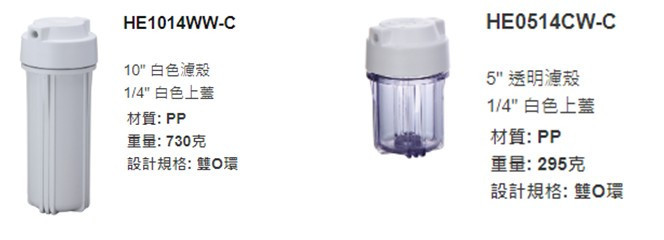

The filter bottle used in household water purifiers is generally 10 inches in length and typically comes in two styles: white and transparent.

| 1. Filter bottle material: PP, AS, PET, and stainless steel. |

| Description: Food-grade raw materials. The most commonly used materials are PP (polypropylene, usually white) and AS (styrene-acrylonitrile resin plastic, usually transparent), also known as SAN. The better the material of the filter bottle, the greater its resistance to pressure. The thickness of the filter bottle also affects its pressure resistance and strength. In theory, a greater thickness results in higher pressure resistance and strength; however, this also increases weight and cost, so the thickness must be appropriate. The two most commonly used plastic materials in the water purification equipment industry are PP and AS. Firstly, they are reasonably priced. Secondly, they are non-toxic. Thirdly, they are easy to store and process. We will analyse their characteristics using the following two items: PP Features: High impact resistance with strong mechanical properties: PP is most suitable for filter bottles subjected to high water pressure and can withstand water hammer without breaking. Resistance to a variety of organic solvents, as well as acid and alkali corrosion: In industrial water, there is often a high level of acidity or alkalinity, and PP plastic can withstand these particular water conditions. AS Features: Good light transmission: This allows for easy visual assessment of the contents (for example, whether the filter core is dirty). Greater heat resistance: Outdoor water temperatures can often reach 50-60 degrees Celsius (e.g., in Middle Eastern countries), making AS material a preferred choice for water filtration equipment manufacturers. Improvement of both mechanical and chemical properties: This advantage is similar to that of PP plastic materials. AS Disadvantages: Strong rigidity. Compared to PP, it is less resistant to water hammer and water pressure, unless the product design structure is reinforced or the thickness of the filter bottle is increased, which will raise material costs. |

| 2. Inlet and outlet pipe diameter (interface size): 1/4″ (2 points), 3/8″ (3 points), 1/2″ (4 points), 3/4″ (6 points), 1″ (one inch) |

| Description: Most household water purifiers use 1/4 inch (2 points) pipes, and if they are used in water towers, most of them are 1 inch. The size of the pipe diameter affects the flow of water from the filter bottle. If the water output of a typical household water purifier is too large (more than 3 points), the filtering effect of the filter core will be diminished, as the flow rate during filtration is too fast to absorb sufficient impurities from the water or to remove chemical substances in the water, such as residual chlorine, pesticides, calcium and magnesium ions, heavy metals, etc. |

| 3. Filter bottle color: white, black, clear, blue, or special color. | |

Description: The standard configuration of commonly used water purifiers is: three. The first is transparent, while the second and the third are white bottles.  |

4.Length: 5 inches, 10 inches, 20 inches | |

Description: General household is 10 inches |

5.Diameter: 2.5 inches (little fat) or 4.5 inches (big fat). | |

| Description: It depends on the demand; the standard household filter bottle has a diameter of 2.5 inches, while the filter bottle for water towers is usually 4.5 inches. (The 2.5 inches and 4.5 inches refer to the outer diameter of the filter element itself and not the filter bottle.) |

| 6.Water-stop O-ring: single O-ring or double O-ring. | |

Description: These are important components whose main function is to seal or prevent water leakage when the machine is working |

7. Air release button (pressure relief button): 1/4 inch (mostly not attached), 1/2 inch (most of the above sizes will have an air release button). | |

Note: When replacing the filter element, gently press the pressure relief button to release the pressure in the bottle, ensuring that no air remains in the filter bottle, which allows for a smooth water discharge. |

8. Inlet and outlet threads: NPT, PS, and BSP. | |

| Description: American and British standards are the two major threads currently used in the United States and the United Kingdom, respectively. American regulations (NPT/NPS) and British regulations (BSPT, R/BSPP, G) are commonly employed in Taiwan. The American National Standard Pipe Thread Standard, commonly referred to as the National Pipe Thread Standard, is the technical standard for threads used on American National Threaded Pipe and fittings. British Standard Pipe, a thread standard widely used internationally, includes the mating of external threads and internal threads (female threads). It is equivalent to the US NPT standard and is often used as a thread standard for pipes and pipe fittings. |

In addition to the above specifications for filter bottles, the housings are also categorised under the following names.

Quasi-type filter housing Length: 5″/10″ Water inlet and outlet: 2 points / 3 points / 4 points The more commonly used colors are: transparent/white/blue  |

Small fat filter housing 2.5″ diameter Length: 10″/20″ Water inlet and outlet: 3 points / 4 points / 6 points The most commonly used colors are: transparent/blue Often designed with an air release button  |

Big fat filter housing 4.5″ diameter Length: 10″/20″ Inlet and Outlet: 1″/1.5″ The more commonly used colors are: transparent/blue Designed with an air release button  |

Other types of filter housings RO membrane shell / ceramic filter element shell / special filter shell for water dispenser  |

(5) List of 100 manufacturers of water purifier filter housings in Taiwan.

| Company Name | Capital(TWD) | Website | Addresss | Social Network | EDM URL | Insurance | litigation | Product | Own laboratory | Client | |

| 1 | Kemflo (Nanjing) Environmental Technology Co, Ltd | $724,000,000 https://reurl.cc/M06b74 | http://www.kemflo.net/ | No. 3, Huandong St., Pingtung City, Pingtung County 90093, Taiwan (R.O.C.) 99則/2.9分 | N/A | N/A | N/A | https://lihi2.com/9pBIM | http://www.kemflo.net/products_lsit222.html | http://ft.kemflo.net/intro/8.html | N/A |

| 2 | MULTIPLY INDUSTRIAL CO., LTD. | $47,000,000 https://reurl.cc/anZkl7 | http://www.multiply.com.tw http://multiply.en.alibaba.com/ | 7 F., No. 21, Ln. 248, Sec. 4, Zhongxiao E. Rd., Da’an Dist., Taipei City 10692, Taiwan (R.O.C.) | N/A | N/A | N/A | https://lihi2.com/7mCFJ | http://www.multiply.com.tw/showroom1.html | N/A | N/A |

| 3 | ORGANIC FILTER CO., LTD. | $110000000 https://reurl.cc/0p42zA | www.organic-com.com | No. 1, Aly. 78, Ln. 38, Sec. 1, Yuanlu Rd., Dongxi Vil., Xihu Township, Changhua County 51449, Taiwan (R.O.C.) | https://zh-tw.facebook.com/OrganicFilter/ | N/A | N/A | https://lihi2.com/Ovcqb | http://www.organic-com.com/products.asp | N/A | N/A |

| 4 | EASYWELL WATER SYSTEMS, INC. | $60,000,000 https://reurl.cc/o1VeLD | https://www.easywellwater.com/tw | No. 222-1, Sec. 2, Jiadong Rd., Changhua City, Changhua County 50084, Taiwan (R.O.C.) | https://easywell.tw.taiwantrade.com/others/9604 | https://alyawater.com/product/sf-123fm/ | https://lihi2.com/dWxzH | https://www.easywellwater.com/en/product/pro | https://www.easywellwater.com/tw/about/31 | BWT |

If you would like to learn more about the supplier list, please fill out the form and get in touch with us.

Further Reading :2022 Taiwan Water Purifier 【Filters】 OEM/ODM Manufacturers – Water Purifier Supply Chain Top 100 Manufacturers Series 1