Our Persistence

Since its establishment, Yirui has regarded quality control as its second lifeline, committed to producing high-quality products that meet customer needs.

1. Collaborative success: Through SCM (Supplier Chain Management), we assist in improving the delivery quality of our suppliers, creating a win-win situation for all.

2.Product requirements: The primary demand is that products must be harmless to humans, with high quality as the foundation. Only after that do we consider functionality and cost.

3.Product development requirements: Before a product is launched, it must undergo more rigorous tests than NSF standards, including lifespan and toxicity tests. To date (2021), we have invested 18 million NTD in building a professional quality testing centre. Testing covers filter housings, cartridges, individual parts within RO systems, such as booster pumps, four-way valves, high and low-pressure switches, storage tanks, PE pipes, gooseneck faucets, and more. Only after ensuring the quality of these components do we bring the products to market.

4.Strict quality control: Every product is subjected to 100% testing during production before it is shipped.

5.Continuous improvement: We adhere to a philosophy of continuous improvement, believing that even good products can be made better. Based on valuable customer feedback, we improve our products to enhance user convenience and better meet customer needs.

Quality Policy

- Never compromise and insist on the highest quality.

- Utilise top quality as our competitive advantage.

- Top quality is our shared standard.

- Zero defects represent our behavioural value.

2024 Quality Goals

- Customer damage claims: less than US$7,000 per year

- Lead-time achievement rate: above 98% per month

- Average production efficiency: 90% and above

- Industrial safety accidents: 0 cases per month

- Management process reviews: 1 or more times per year

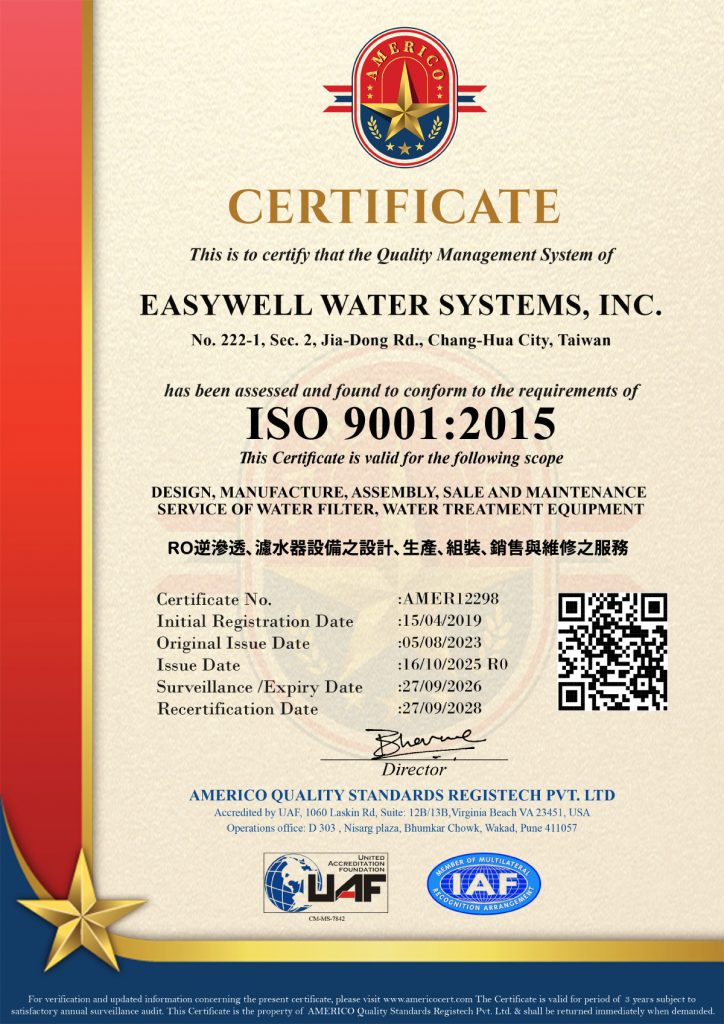

Easywell obtained ISO-9001 international quality certification in 1999 and has since maintained rigorous control over product quality. The company adheres to a daily regimen of quality control and assurance practices, including:

- Deployment of golden samples on the assembly line

- Initial and final product inspections

- Ongoing inspections

- Random spot checks

- Independent inspections

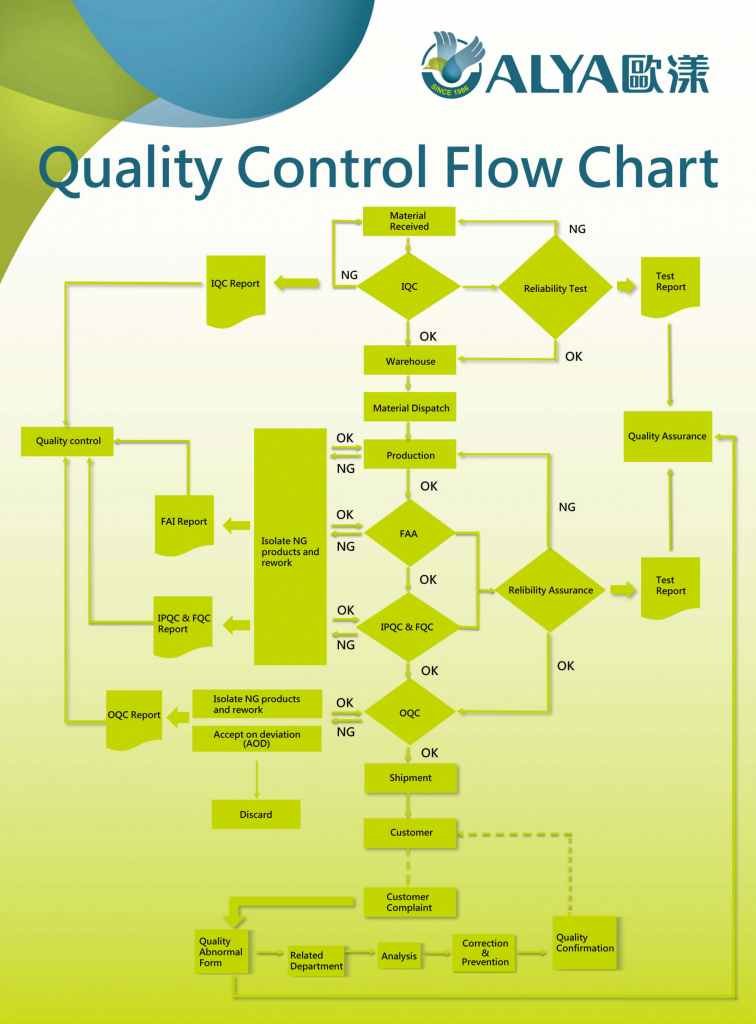

In the inspection of finished products and semi-finished products, we also implement the following quality assurance methods at all times:

- IQC (Incoming Quality Control)

- IPQC (In Process Quality Control)

- PQC (Process Quality Control)

- FQC (Final Quality Control)

- OQC (Out-going Quality Control)

‘The above insistence exists to ensure that the quality of each shipment is consistent.'”