When entrusting products to an OEM manufacturer, control of the production schedule and commitment to delivery performance are very important. In addition to legal constraints through contracts, we can also observe the OEM manufacturer’s usual work processes to gain a clearer understanding of whether their commitment to delivery performance is reliable.

This article takes the example of a fire at an OEM manufacturer and discusses how to protect the customer’s rights and interests while ensuring the smooth execution of delivery performance.

Internally, they will conduct steps such as checking for casualties, assessing the extent of damage, evaluating the possibility of resuming operations, preparing materials, and undertaking emergency procurement. Externally, they will notify the bank, subcontractors, and customers, explaining the situation regarding the fire and discussing delivery dates, as well as issues concerning deposits.

If the customer chooses to transfer orders to other parties or wait for production to resume, the company will provide support and take responsibility for introducing other companies that can produce the same products to the customer.

Finally, the article points out that even if the profit from operating an OEM manufacturer is minimal, investment in fire safety equipment is essential; otherwise, the incidence of fires will increase, adversely affecting the interests of both OEM manufacturers and customers.

1. Fire at a Water Purifier Factory in Taichung

According to a local television news report in Taiwan, a manufacturer of water purifiers located in Taichung City experienced a devastating fire on the night of 1st December 2022. The entire factory was engulfed in flames, causing extensive damage to the buildings, production equipment, inventory, and nearly everything else. Such an unfortunate incident is something that none of us would wish to witness or endure.

Therefore, ensuring that the production plants of contract manufacturers are not affected by fire disasters is an issue that cannot be overlooked. It is essential to provide reassurance to purchasing agents that their supply chain will not be disrupted due to a fire at the manufacturers’ factory.

2. Fire safety regulations are becoming increasingly stringent.

According to local news reports in Taiwan, in May 2022, the government revised the fire safety laws once again. The fire safety regulations for factories are also relatively strict. Currently, they have been aligned with those of European and American countries and have reached the same rigorous standards for inspection. A minimum of one inspection visit to the factory is required each year.

The regulations stipulate that factories must employ a fire equipment engineer who holds a “fire equipment licence” or commission a fire equipment engineering company to comply with the government’s fire equipment inspection requirements.

3. OEM manufacturers attach importance to fire safety.

Although regulations are becoming stricter, OEM manufacturers do not give adequate attention to fire safety; the occurrence of a fire is unlikely to be purely accidental.

Whether daily electricity usage or equipment usage is overloaded, whether the transmission cables supplying electricity are old and require updating, whether ageing production machines and equipment are prone to spontaneous combustion, whether extension cords and power sockets are used improperly, and whether lithium battery-powered mobile devices are charged independently, all these safety measures implemented in daily work will affect the likelihood of fires occurring.

4. Reviewing Easywell Company’s Fire Safety Practices

At the same time as this incident involving the water filter company, we at Easywell Company take this opportunity to review our fire prevention and safety measures to ensure that our customers’ interests are not jeopardised due to fires.

1. Safety Measures for Mobile Tools Prone to Spontaneous Combustion

The batteries used in forklifts are typically lead-acid batteries. As we often charge them at night, we implement the following preventive measures to avoid incidents of battery spontaneous combustion:

1.1 Installing overload safety devices on the charging receiver to automatically cut off the power supply to the forklift and charging receiver in the event of battery combustion, ensuring the first stage of safety.

1.2 Parking the forklifts outdoors to prevent indoor facilities from being affected in the event of combustion, thus prolonging the burning time.

1.3 Installing a suspended automatic 10-type ABC dry powder fire extinguisher on the forklift, which will automatically extinguish the fire in the event of forklift combustion.

1.4 Some of the transportation used by employees of Easywell Company includes electric bicycles. To prevent the risk of self-ignition during charging, we have positioned the charging and parking areas for electric bicycles outside, thereby minimising the risk of battery spontaneous combustion.

1.5 We also use safe power sockets.

When the electric bicycles are charged outdoors, Easywell Company proactively installs safety sockets with automatic overload protection and requires our team who ride electric bicycles to plug them only into the designated safe sockets.

1.6 Lithium Battery Charging Zone

To prevent the risk of overloading and self-ignition due to nighttime lithium battery charging, which may lead to fires, we have installed several timer switches for equipment such as electric forklifts, rechargeable cordless drills, electric pallet jacks, electric scissor lifts, hydraulic lift platforms, and others. When the charging process begins, each session is limited to a maximum of 6 hours before automatically stopping, thereby preventing overcharging incidents even after reaching full battery capacity.

2. Strictly control improper use of extension cords

At the workplace or employee dormitories, it is essential to strictly control or prohibit the use of extension cords. This can ensure that users do not overload the cords, which may lead to electrical fires due to exceeding the load between power outlets and the cords.

3. Use power cords that meet safety standards

The electrical wiring in the factory is regulated prior to subcontracting, and the use of power cords requires products that bear the correct markings.

4. Entrust licensed electricians to maintain all electrical equipment in the factory

In daily operations, if there are electrical faults or an increase in power demand, Easywell Company insists that subcontractors must possess a government-approved electrician’s licence.

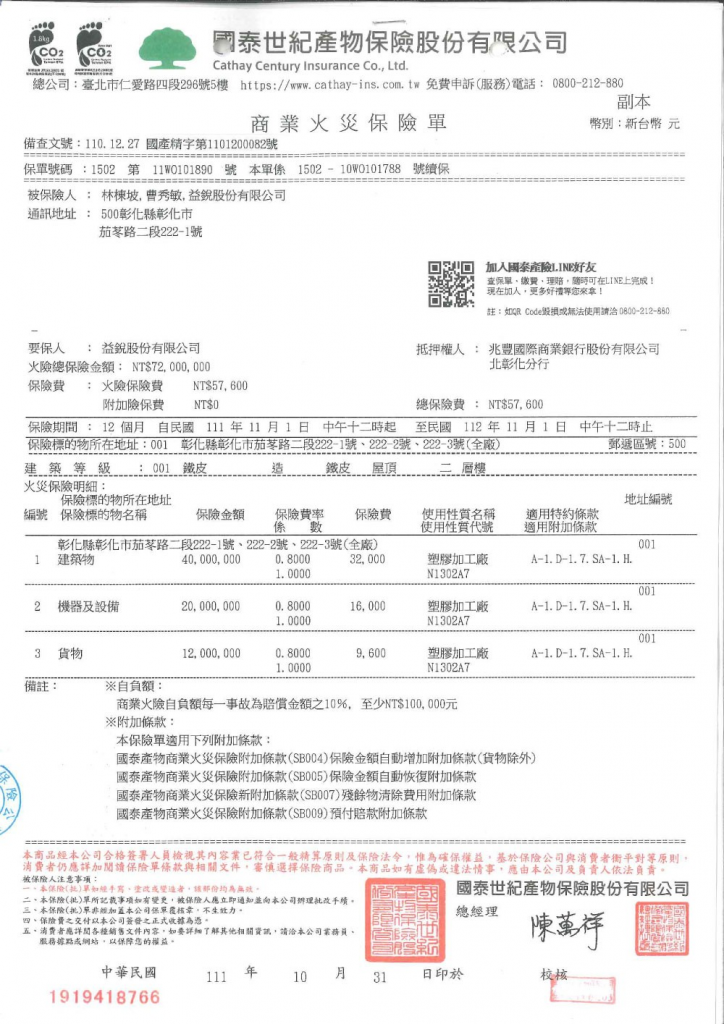

5. Purchase sufficient fire insurance annually

This ensures that, in the event of a fire accident, the subcontractor can utilise the insurance payout as a fund for swift recovery.

6. Inspector Checks Important Power Usage Daily

Every day, during a 10-minute break in the morning and afternoon, as well as after work, a designated person inspects whether important machinery has been properly shut down to prevent accidents caused by electrical fires resulting from abnormal power systems when left unattended.

7. Disseminating Fire Prevention Precautions Regularly

We require the management department to download one or more fire prevention information videos from YouTube for everyone to watch during the monthly education and training day, to enhance everyone’s awareness of fire safety.

8. Conduct Fire Drills Annually

Fire drills are a significant matter for us, and we require every partner to use fire extinguishers and high-pressure fire hoses.

9. According to the law, licensed electrical technicians are employed every year to inspect all high and low voltage electrical circuits and equipment.

10.The entire plant is equipped with smoke detectors and automatic smoke extraction devices in compliance with the law.

11.Fire hydrants and fire hoses are installed throughout the plant in accordance with the law.

12.Additional automatic fire sprinkler systems have been installed.

In addition to installing fire hydrants and fire hoses in accordance with regulations, we have also installed automatic sprinkler systems on the ceiling in key working areas.

- More comprehensive fire extinguishers and automatic power outage lighting equipment are installed than required by law.

- Fire broadcasting system equipment is installed in compliance with the law.

- The fire broadcasting system is connected to the security service centre. When a fire occurs, the fire alarm signal is automatically sent through the fire broadcasting system and synchronously relayed to the control centre of the security service company. The on-duty security personnel will also notify the management staff of Easywell by phone immediately and conduct on-site investigations while informing the fire department to take immediate fire-fighting actions.

- We insist on using fire-resistant building materials. To ensure the safety of personnel and property, Easywell Company has insisted on using fire-resistant building materials when constructing and designing the plant, including the dormitories where foreign partners reside. For example:

- All wall partitions are made from calcium silicate boards.

- The ceiling is constructed from a lightweight steel structure and calcium silicate board.

- The generator and fire pump are installed in compliance with the law. The installation of the generator is primarily to prevent the external power supply from being compromised by the fire source during a fire, which could lead to a power outage, rendering all fire-fighting equipment that relies on electricity useless. The automatic power switch, known as ATS, will start the generator and automatically activate the fire pump, ensuring that the fire system can operate normally during a fire.

- Smoking is prohibited throughout the plant. Since its establishment, Easywell Company has strictly prohibited smoking inside the plant, imposing heavy penalties for violators. There are warning signs displayed prominently stating, “A fine of 3,000 NTD will be imposed on guests who smoke in the plant.”

Of course, we also have a designated smoking area for smokers to indulge in their habit safely.

- Important files are regularly backed up. To prevent the computer hardware from being destroyed in a fire, resulting in the inability to recover software information after the hardware has been restored, we regularly back up important files and utilise remote backups in different locations to ensure data security.

5. If there is a fire, how does Easywell protect the rights and interests of its customers?

In order to be responsible to our customers, shareholders, employees, and suppliers, we have established the following standard operating procedures (SOP) in the event of a fire:

Internal Procedures:

Firstly, we will convene a meeting of all senior executives to discuss follow-up matters immediately after extinguishing the fire.

- Check if there are any injuries among the staff. What is the extent of the injuries? Do they require medical attention?

- Assess the extent of the damage.

- Determine if there is a shortage of raw materials needed to resume work.

- Is it possible to resume work? How long will it take?

- Inform all employees that we will resume work and provide additional compensation to those who assist at the fire scene.

- Reach a consensus with our partners regarding salary payments during the period when work cannot be resumed, in order to provide stability.

- Determine whether it is necessary to prepare materials in advance.

- If materials need to be prepared, utilise backup ERP inventory software information to decide on the emergency procurement of materials and spare parts that are in short supply due to the fire.

External Procedures:

- Inform the bank of the cause and circumstances of the fire, and request that they do not withdraw any funds.

- Inform partners of the fire situation, explain the financial stability of Easywell Company, and request their continued support.

- Inform all customers and provide detailed information on the fire situation, including the anticipated timeframe for resuming production and delivery times.

- Explain how the deposit paid by customers to Easywell will be held until the goods are shipped.

- If customers choose not to wait and decide to transfer their orders to other companies, Easywell will unconditionally refund the deposit to the relevant customers.

- If customers opt not to wait for Easywell to resume operations and cannot find a comparable supplier in the meantime, Easywell will assist by introducing the customer to a peer who can produce the same products.

6. Conclusion

The profit margins for running an OEM factory are often quite slim, leading some owners to cut corners on fire prevention costs in an attempt to save money. Achieving optimal fire safety measures requires more investment than that of other companies, and such investments will consequently diminish the OEM factory’s budget for R&D on new products, machinery purchases, and so on.

However, the cost of fire safety equipment and business profits present a chicken-and-egg dilemma. Without increased investment in fire safety equipment, the risk of fires occurring will escalate.

When a fire does occur, the OEM factory may find it impossible to recover. Even if it is capable of resuming operations, the preparation, reconstruction, and reassembly of the original team can be time-consuming. During this downtime, can the buyer tolerate a situation where there are no goods available for sale? This once again tests the mutual understanding and tolerance between both parties.

Author: Rodger Lin, 25 May 2023

“Welcome reproduction; please indicate the source.”