Trading companies, brand owners, and direct selling marketing firms all have their own standard operating procedures (SOPs) for selecting manufacturers. The following are essential criteria for evaluating an OEM:

- Quality

This can be assessed through the manufacturer’s quality management system. Of course, on-site inspections and audits of the subcontractor’s quality can also be carried out, although these methods tend to be time-consuming. - Cooperation

It is difficult to ascertain the level of cooperation from a subcontractor before a transaction. Even if you inquire about or conduct background checks on their existing clients, it is challenging to verify their cooperation. - Delivery Time

Delivery times can be stipulated in the order contract. - Price

(This point was listed but has no elaboration in the original text.) - Responsible Attitude

Determining whether a subcontractor is responsible can be difficult at first. It often becomes apparent only when problems arise with shipped products, requiring assistance, improvements, or compensation from them. - Speed of New Product Development

(This point was listed but has no elaboration in the original text.)

However, when selecting a high-quality OEM water purifier manufacturer, it is crucial to pay attention to the following points. Why is this important? Because water purifiers involve various components, and poor quality can lead to leaks and flooding. In minor cases, this may result in financial losses, while in severe cases, it could lead to legal entanglements.

The following essential criteria can assist buyers in quickly filtering qualified suppliers:

- Possession of Adequate and High-Quality Laboratory Equipment

Before the small-scale trial production of new products, various reliability tests must be conducted in the laboratory. Additionally, during regular mass production, as well as for product design changes and supplier replacements, the following reliability tests must also be carried out:

- Durability Testing

- Burst Testing

- Pressure Holding Testing: Simulating general consumer usage habits

- Pressure Differential Testing

- Salt Spray Testing (for metals)

- Ageing Testing (for plastics)

- Tensile Testing (for plastic pipes/connectors)

- Vibration Testing

- Drop Testing

- Power Supply Testing

10.1 Load Testing

10.2 Temperature Testing

10.3 Leakage Testing

10.4 Voltage Stability Testing - Electronic Component Testing

11.1 Electromagnetic Wave Testing

11.2 Surge Safety Testing

11.3 EMI/EMC Interference Prevention and Non-Interference Testing

11.4 Burn-in Testing - Various Water Quality Tests

12.1 Residual Chlorine Testing for Activated Carbon

12.2 Ion Exchange Resin Testing (for removal of heavy metals and calcium/magnesium ions (scale))

12.3 Bacterial Culturing/Decontamination Testing

2. Purchase Global Product Liability Insurance

No matter how excellent the product is, there will inevitably be some minor oversights that could lead to customer complaints. These issues can be mitigated by purchasing global product liability insurance to protect the rights of customers. However, due to the very slim profits in OEM manufacturing, it is often difficult for manufacturers to justify spending so much money on global product liability insurance.

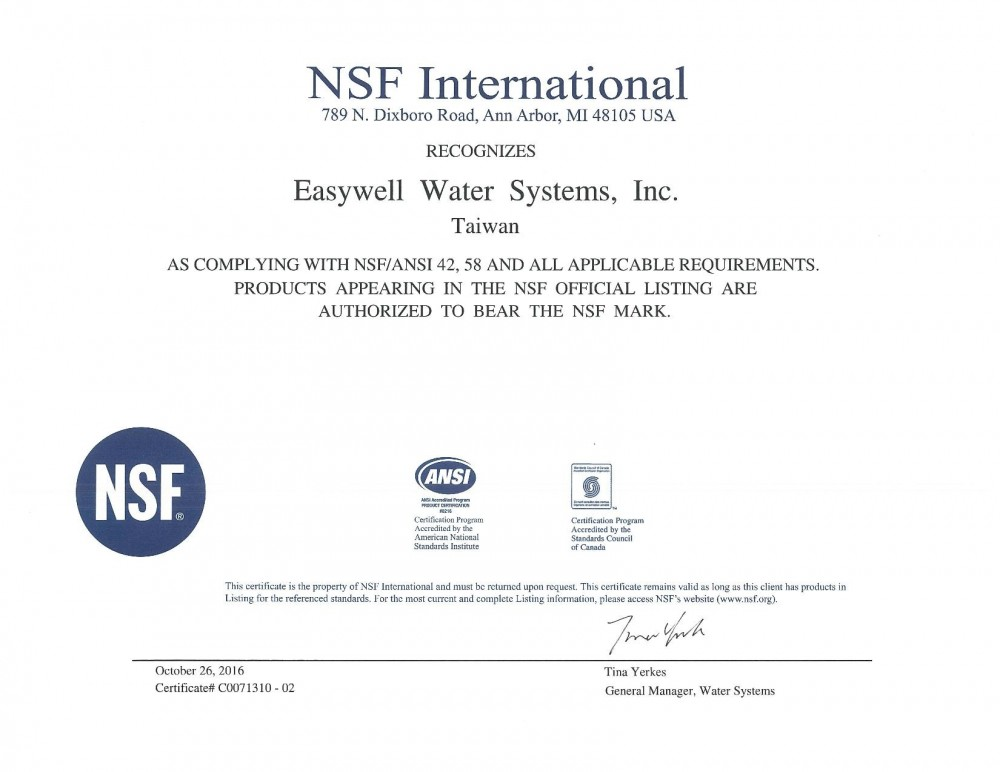

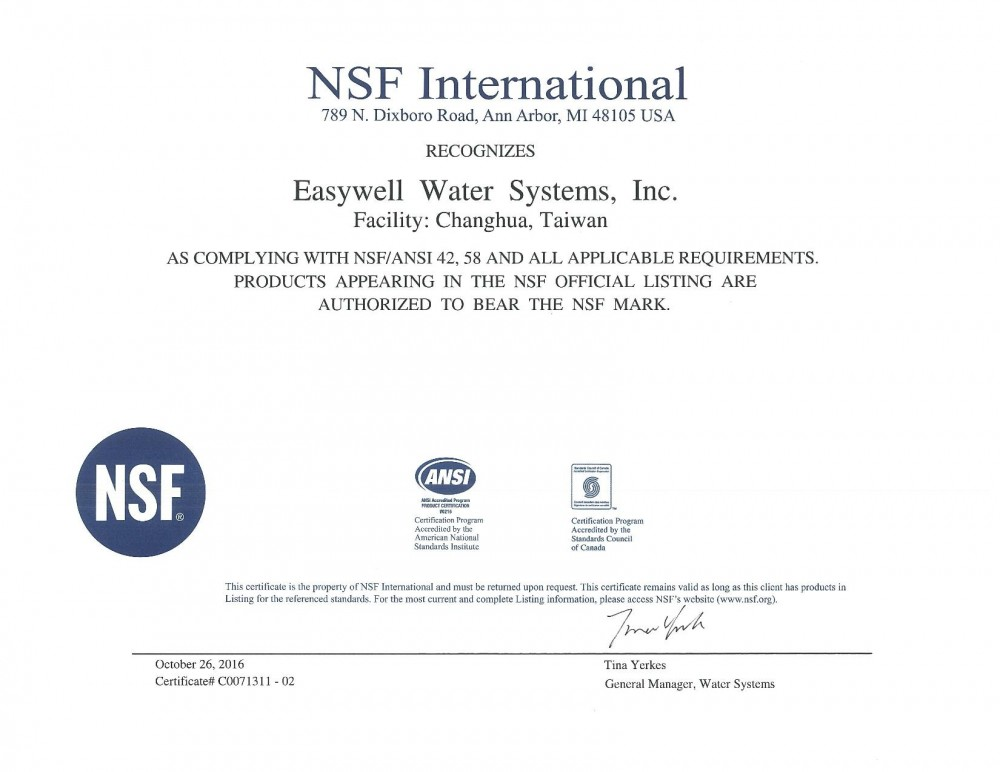

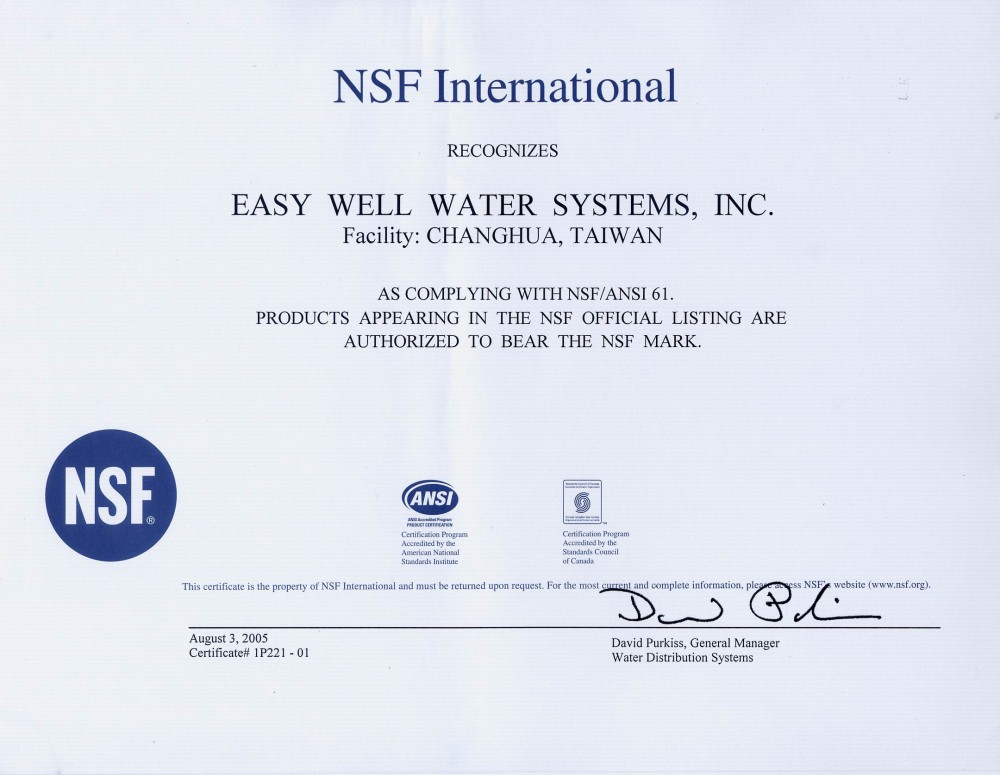

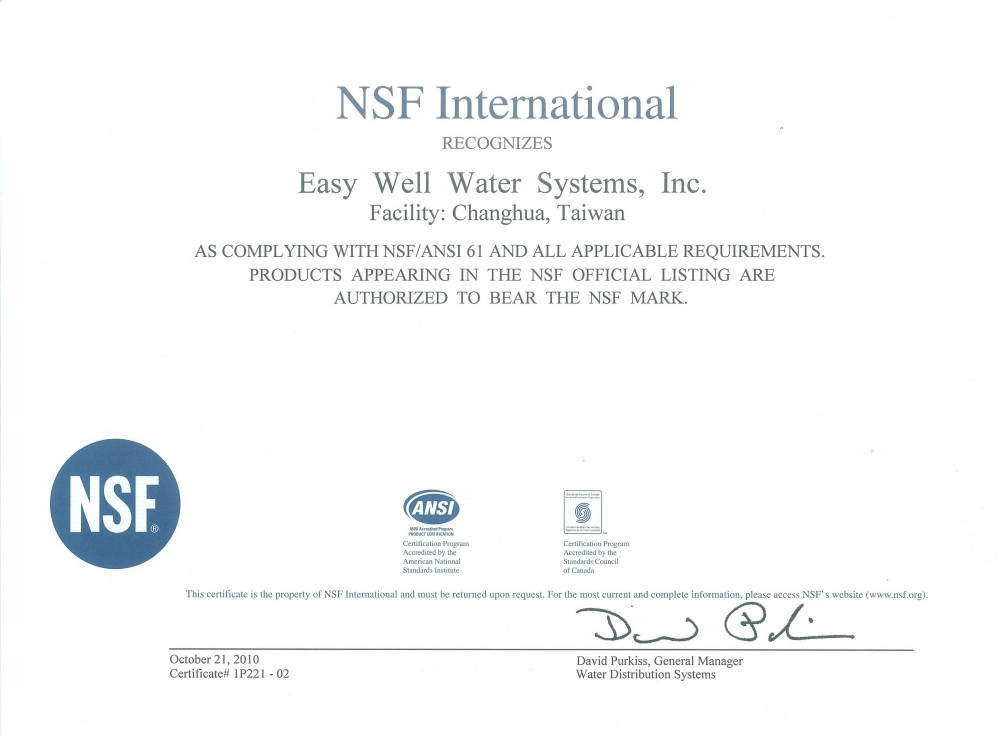

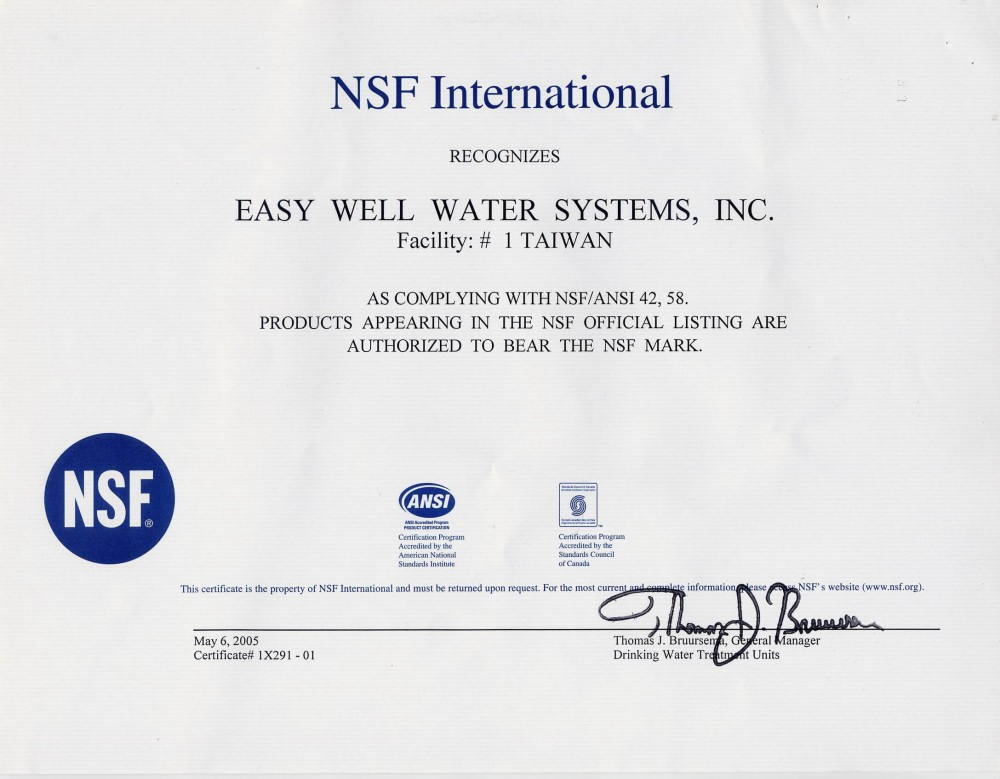

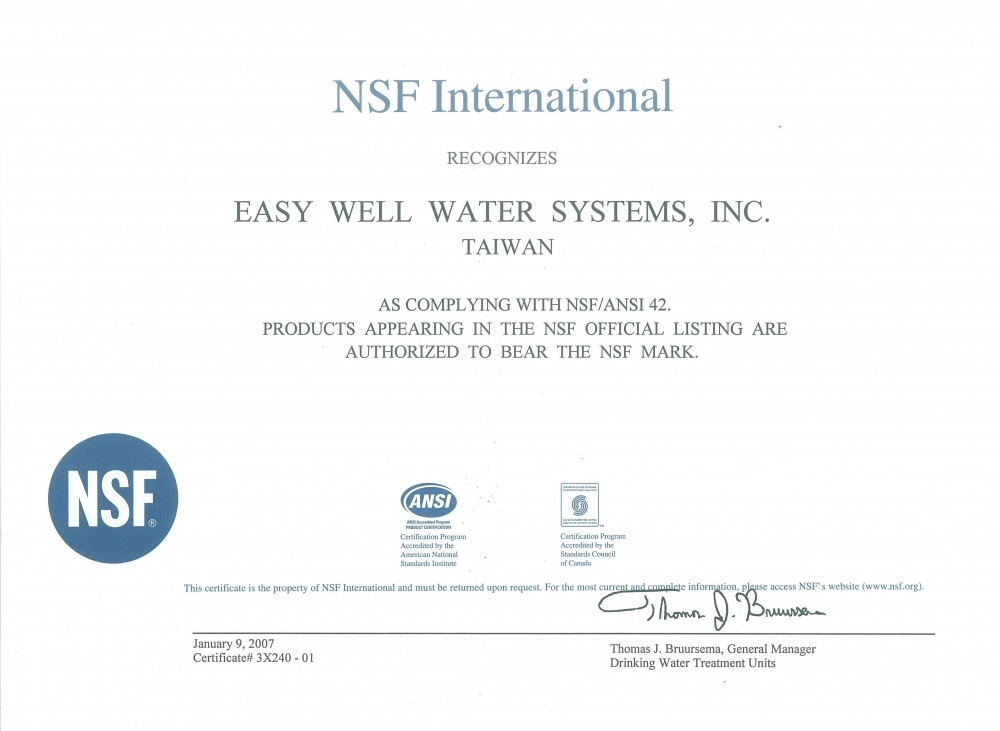

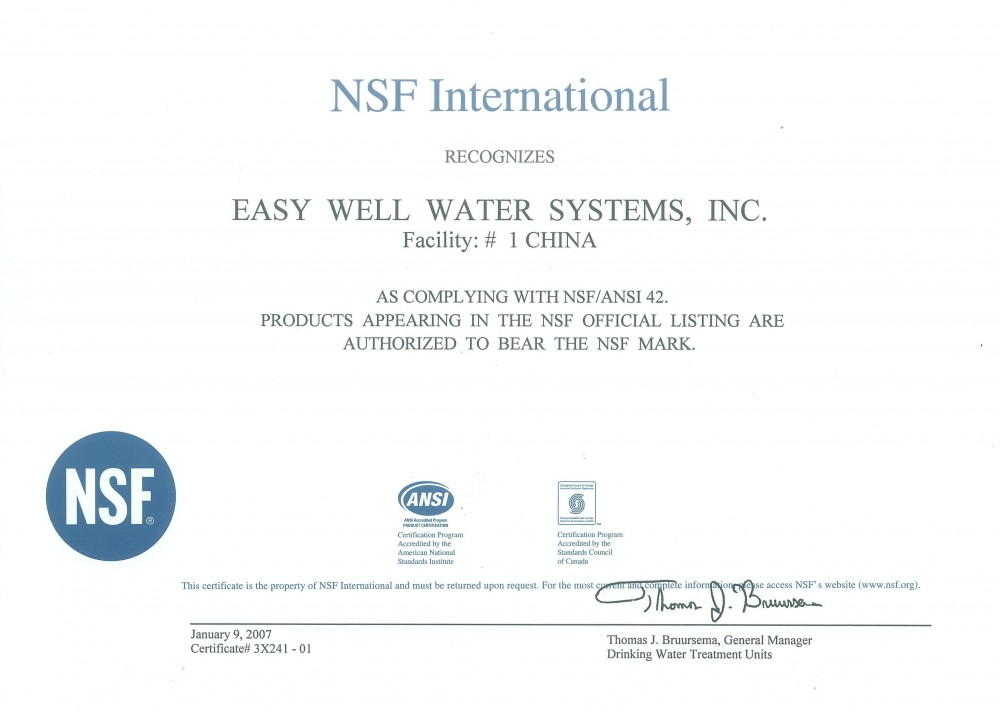

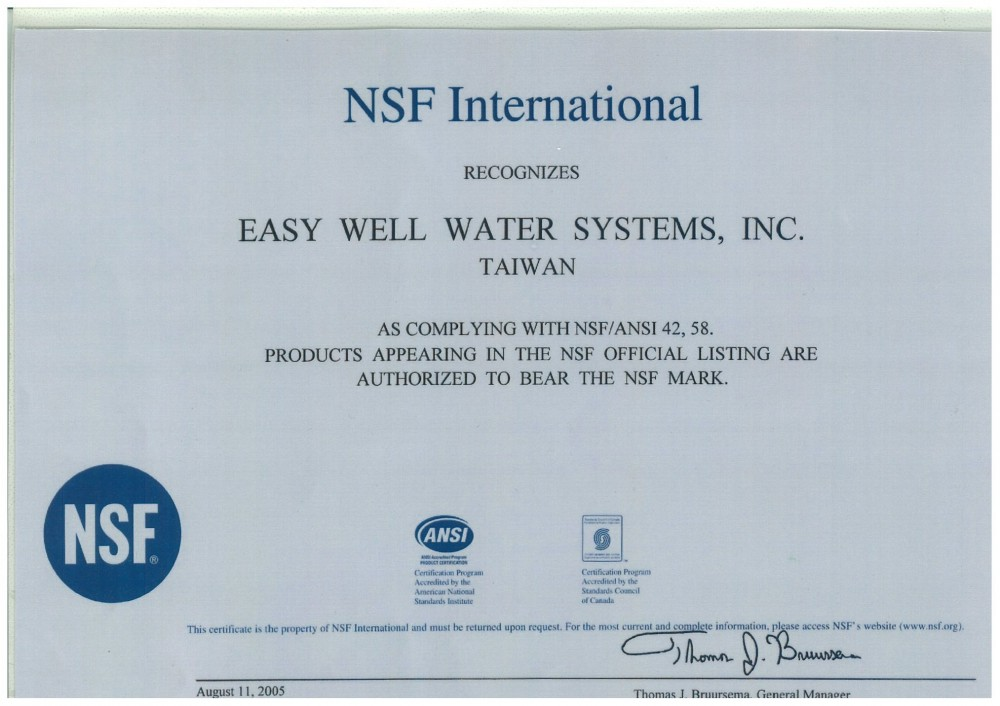

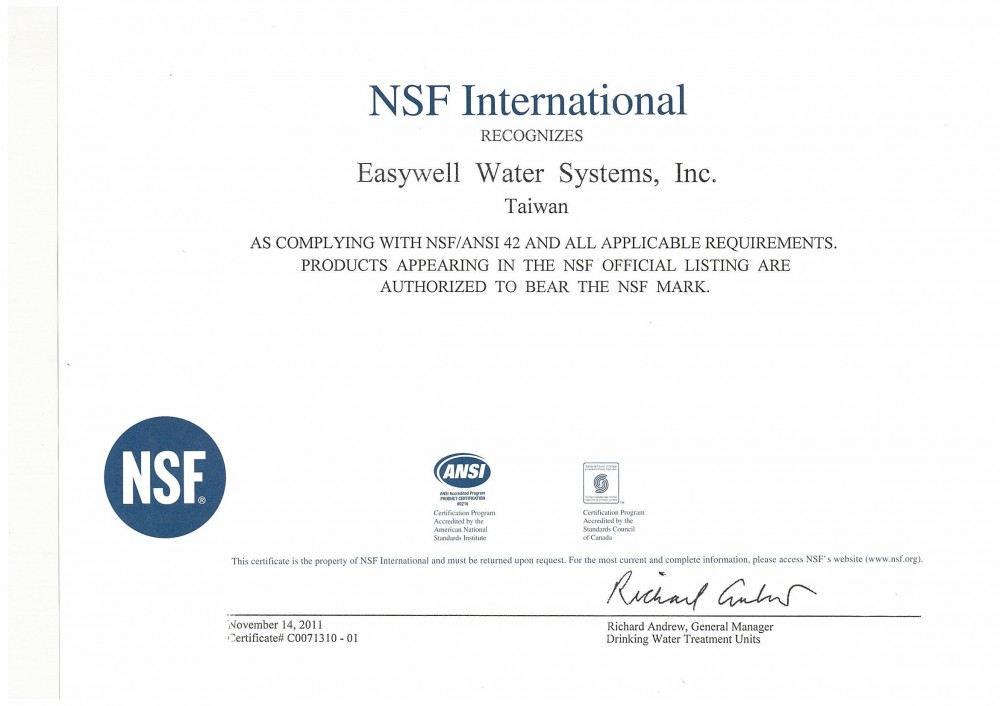

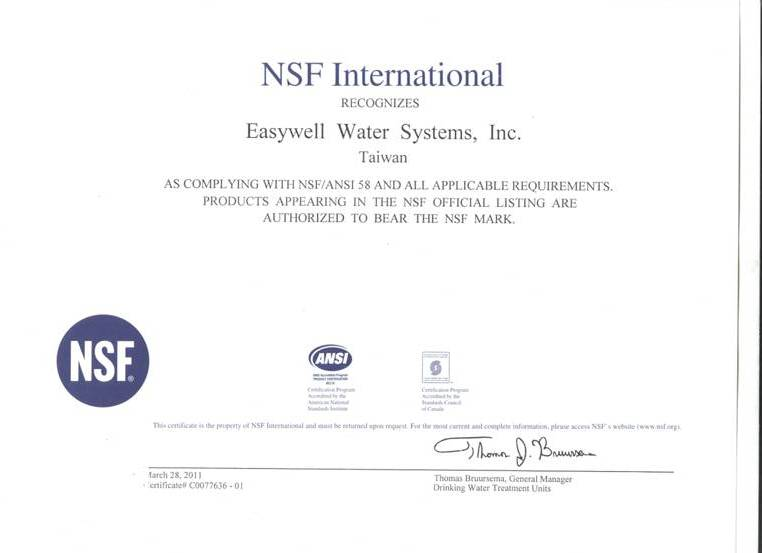

3. Obtain Various International Product Certifications

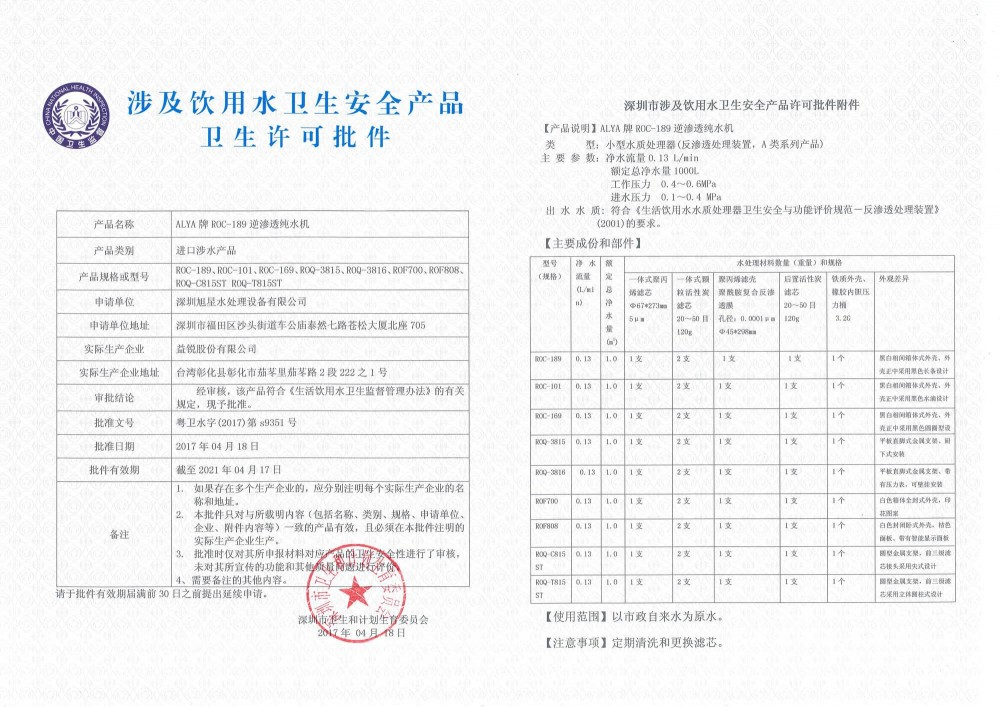

In addition to functionality and quality, the water filtered by purifiers is intended for consumption, which raises important issues regarding whether the purifiers themselves and their filter materials release toxins, their lifespan, and other critical topics. This ultimately depends on whether an OEM manufacturer has the capability and willingness to apply for various international and domestic product certifications. For example:

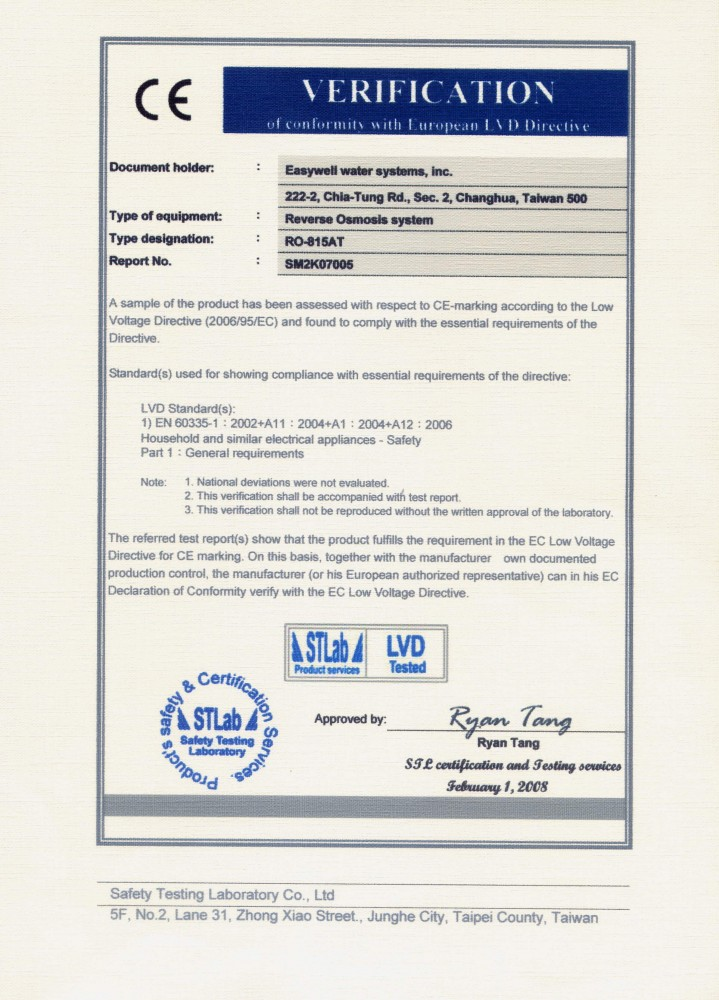

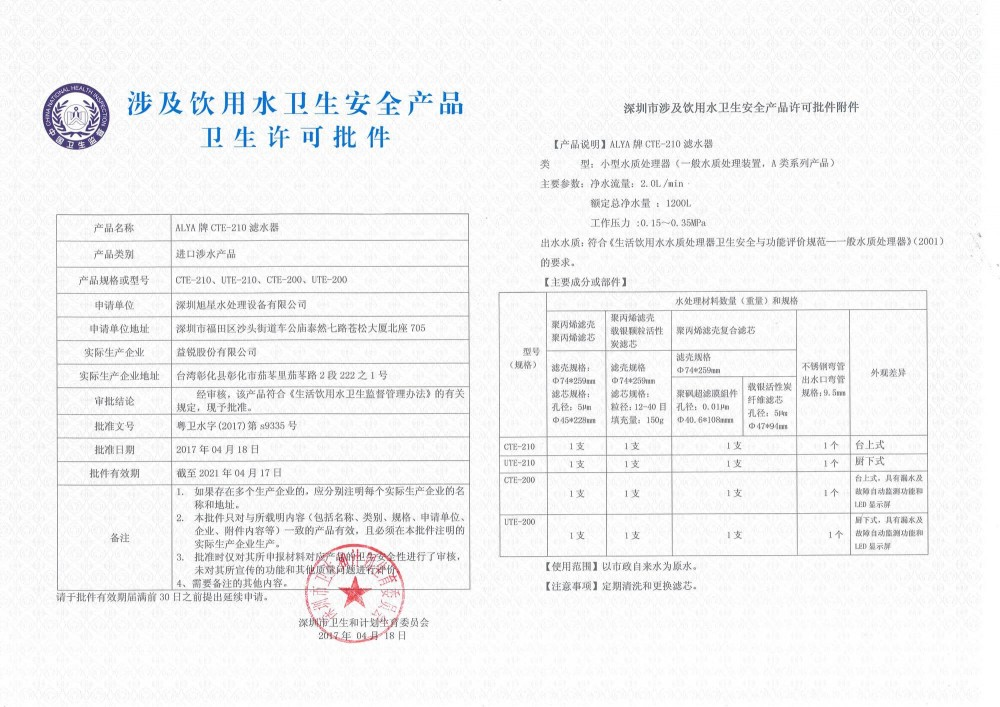

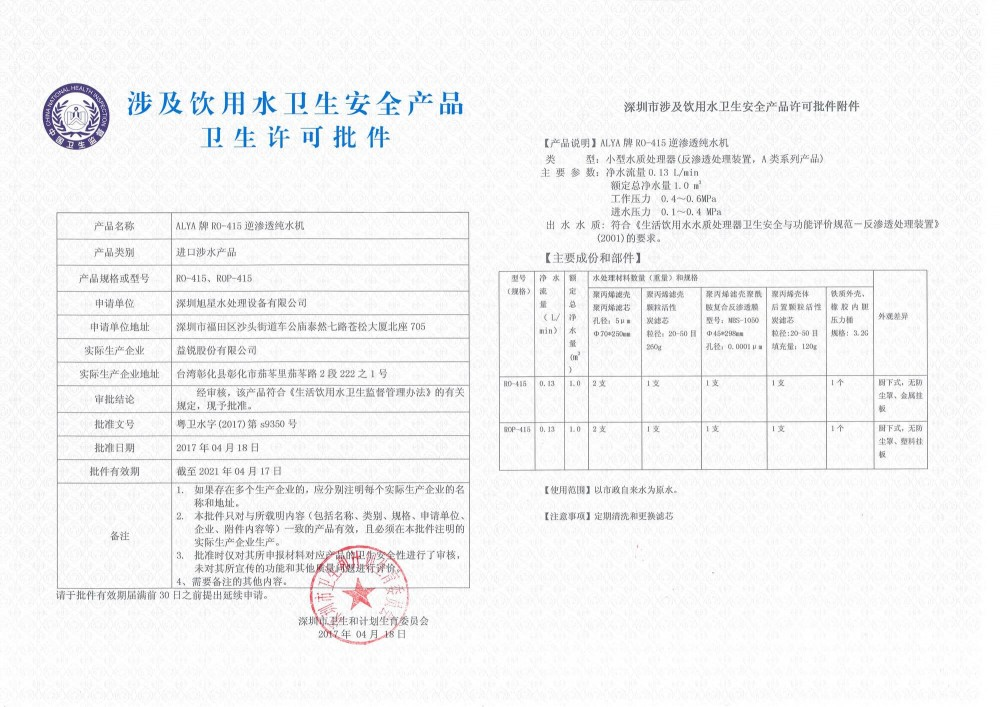

- International product certifications: NSF, CE, RoHS, health approval documents

http://info.nsf.org/Certified/Common/Company.asp?CompanyName=Easywell&x=13&y=11

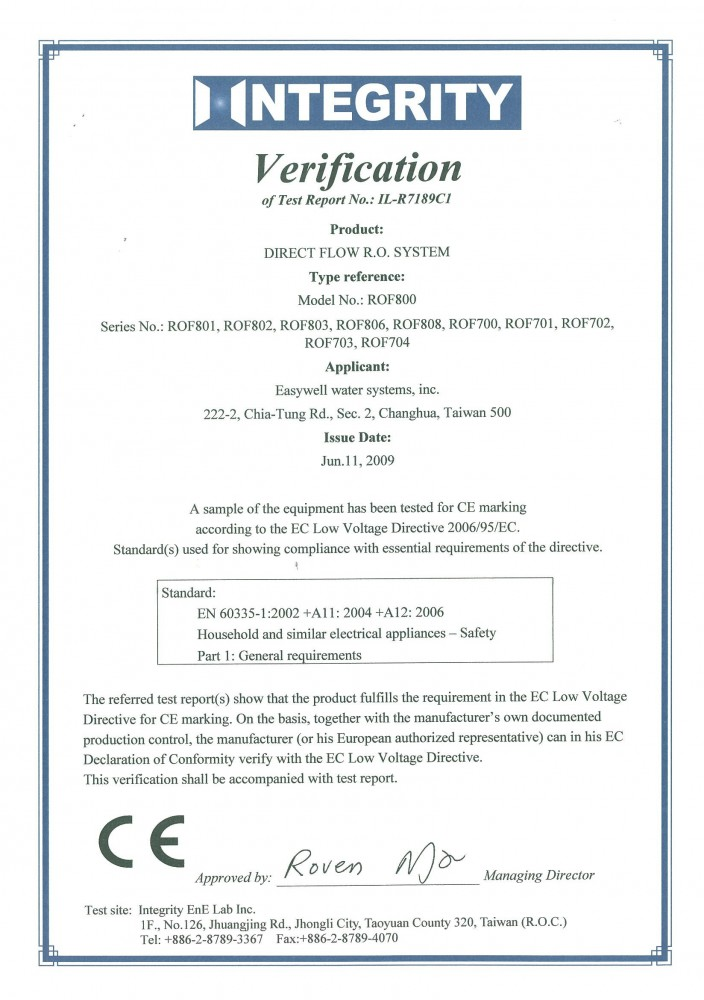

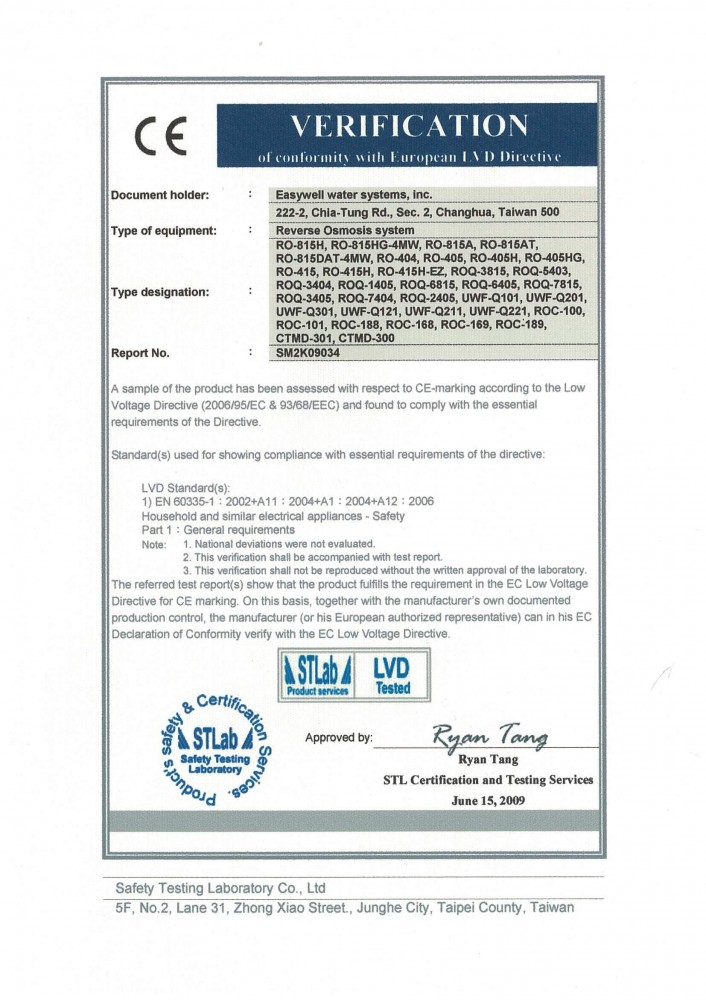

CE Certification of RO System

| CE Certification of Direct Flow RO System |

| CE Certification of RO System |

CE Certification of UV Purifier

| Counter Top Water Filter CTE-210 |

RO System RO-415

| Compact RO System ROC-189 |

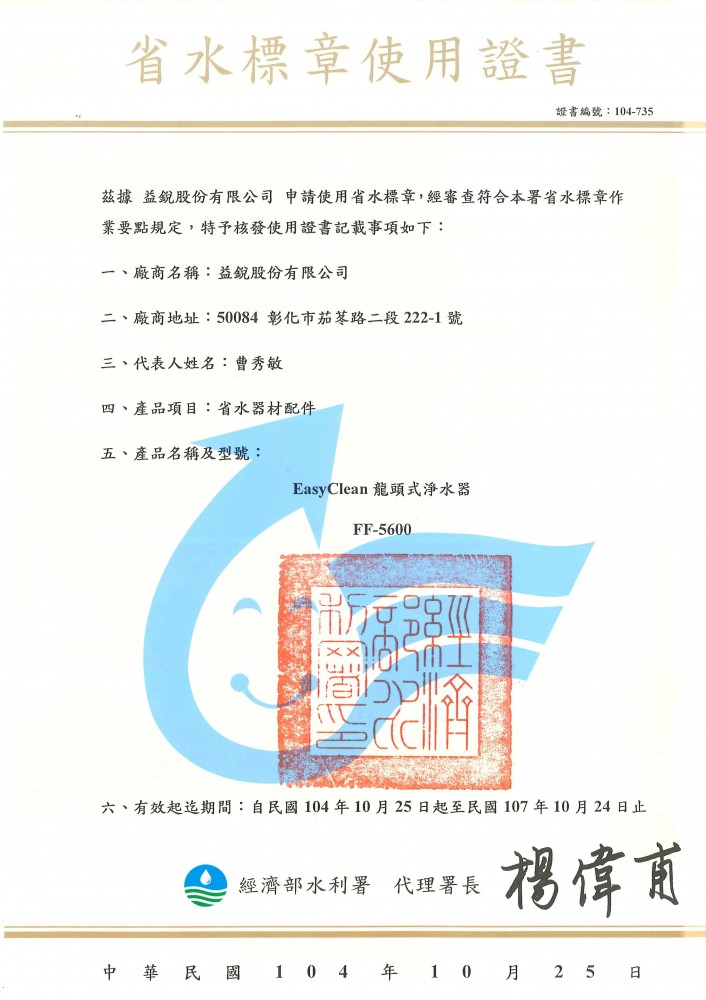

| 2. National product certificates:Water conservation mark, energy saving mark and environmental protection mark. |

| Easy Clean Tap Water Filter FF-5600 Taiwan Water Coservation |

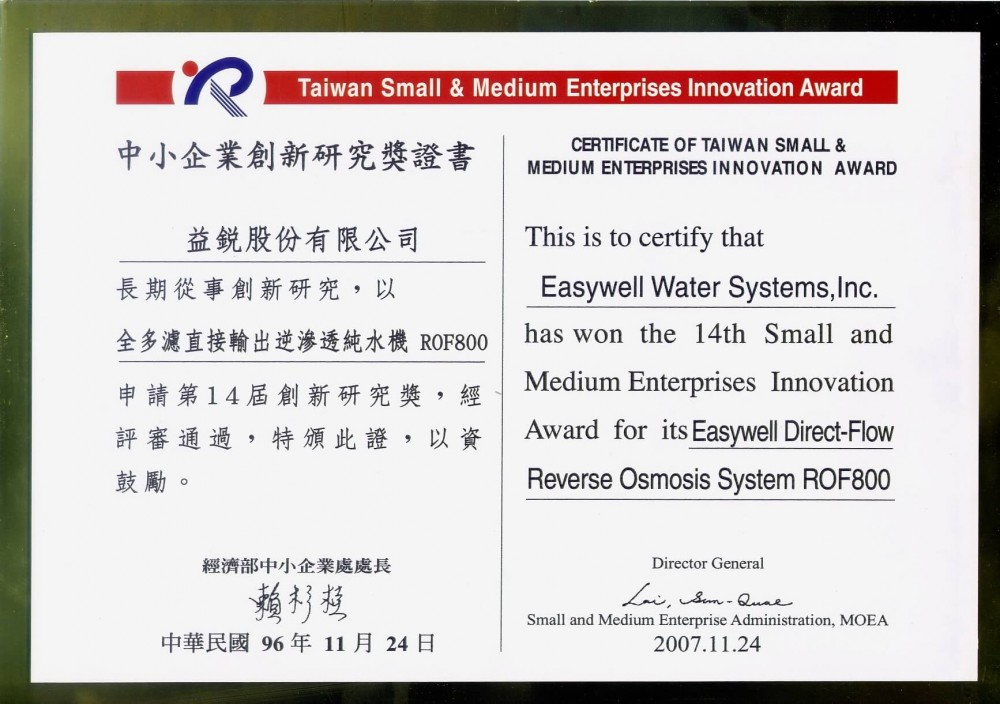

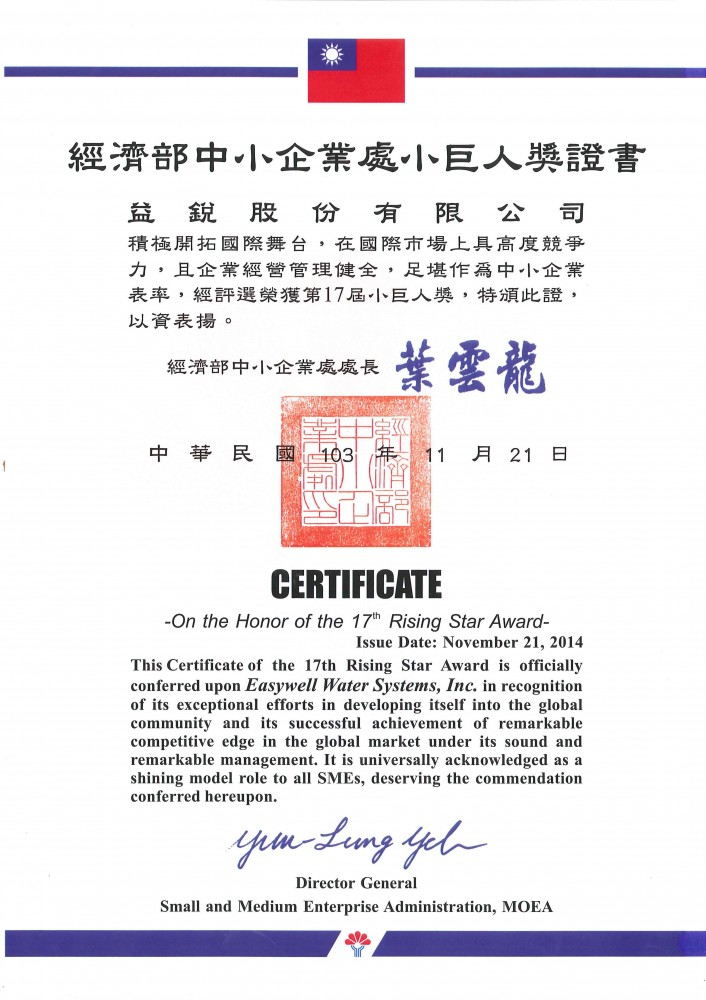

4) The Government’s recognition An excellent and responsible water purifier manufacturer shall inspect its capacity by applying for the Government’s awards, and attempt to prove its achievement with the Government’s recognitions, such as the Rising Star Award, the National Awards of Excellence, the National Award of Outstanding Small and Medium Enterprise, the National Quality Award, and so on. |

5. Finding a Responsible Supplier

In summary of the above points, I personally believe that the most important factor in seeking a manufacturing partner is to choose a truly responsible factory. But how can you tell if your supplier is responsible? The following aspects can provide some insight:

- Whether they purchase adequate global product liability insurance each year

As previously mentioned, water purifiers may occasionally suffer from issues such as tank rupture due to varying water pressures in different countries or improper use, which can lead to significant damage to furniture and carpets during the night or while away for extended periods. If a factory purchases sufficient global product liability insurance each year, it serves as a guarantee of responsibility towards the buyer. - Commitment to quality

If a factory can clearly present its commitment to quality in a public manner, such as announcing it on their website, posting “Quality Commitment” posters throughout the factory premises, or printing their “Quality Commitment” on their business cards, it allows buyers and the public to supervise their practices while continually reminding the factory of their obligations. - Proactive recall of defective products

One of the greatest concerns for buyers is not just the quality issues arising from suppliers, but the suppliers’ indifference towards these issues. A responsible supplier will proactively recall defective products upon discovering any anomalies or potential quality problems. They may offer to replace or amend products locally and compensate the buyer for any incurred losses; this is a true demonstration of responsibility. - Applying for ISO-14001 International Environmental Protection Certification and ongoing compliance

Many suppliers, in an effort to cut costs or due to a lack of environmental awareness, have not obtained ISO-14001 certification. How can we expect such suppliers to have an environmentally friendly mindset? Achieving ISO-14001 certification and maintaining compliance over the years reflects a responsible attitude.

Copyright Notice: All rights reserved. Feel free to repost, but please credit the source.