1. Introduction

At the onset of the new Coronavirus disease (COVID-19) outbreak in 2020, the author wrote a blog article titled “Top Ten OEMs for Water Purification Equipment in Taiwan”. Some of these OEMs faced significant challenges with non-receipt of orders and with their work shifts. Consequently, over the past year, this industry has experienced numerous changes. Some have exited the industry due to poor management, while others now owe tens of millions of dollars to suppliers…

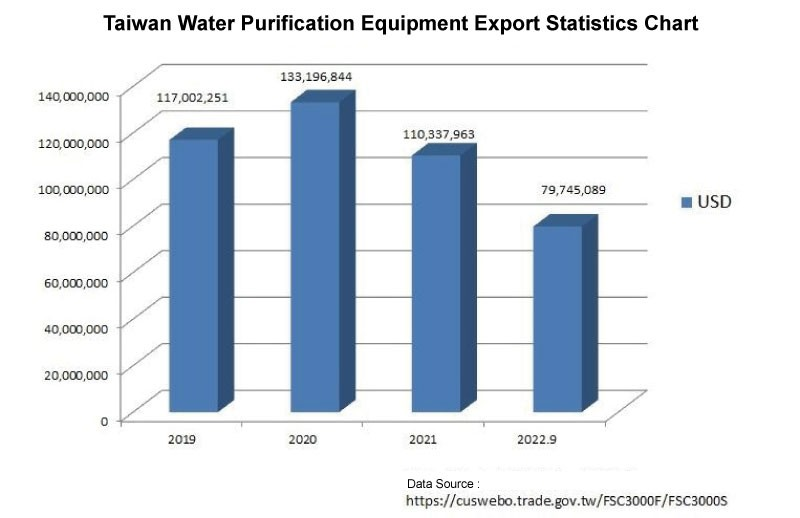

Statistics from previous years and this year indicate that the total value of water purification equipment exported from Taiwan has plummeted.

We don’t know whether the issue that has caused businesses in the water purification equipment industry to decline is related to inflation or to the ongoing war in Ukraine. Perhaps it is connected to the factors mentioned in the book The Fifth Discipline by Peter Senge. Opinions vary.

2. The Characteristics of Original Equipment Manufacturers (OEMs)

At this moment, as circumstances are evolving, the author must reorganise and recommend other excellent OEMs of water purification equipment for the consideration of those wishing to participate.

The following five OEMs of water purification equipment, despite being small or medium-sized enterprises, form the backbone of this industry. All of them are competing for business and concentrating on their own operations. Most have been in business for over 30 years, and they are all trustworthy and successful entrepreneurs. The founders of these OEMs typically share the following characteristics:

- They are sincere, eager, and willing to assist others.

- Their focus is on the water purification equipment industry.

3. OEM Product Line Areas

The recommended five OEMs cover a wide range of product lines:

- OEM of spare parts for water purifiers and pure water machines.

- Design and assembly of water purifiers, pure water dispensers, and water dispensers.

- OEM for LCD and LED key electronic components for water purifiers.

- Design, assembly, and manufacture of electrolysed water machines.

4. Distribution and Location of OEM Manufacturers of Water Purification Equipment

Approximately 60% of the foundries in the water purification equipment industry are concentrated in Taichung and Changhua, with another 20% scattered around Kaohsiung and Pingtung. A further 10% are located in New Taipei City, while the remaining 10% can be found in Chiayi, Hsinchu, Tainan, etc.

Of the five OEMs recommended this time, four are situated in Changhua and Taichung, with the fifth located in Kaohsiung.

5. Advantages of Taiwanese Water Purifier Equipment Factories

Being an OEM for European and American brand factories remains a major feature of most of Taiwan’s manufacturing industry, which is also a strength of Taiwan’s water purification equipment suppliers.

Taiwan’s water purification equipment suppliers not only possess production technical capabilities but also demonstrate a strong quality awareness, as well as the ability to produce items that are both better and cheaper. Additionally, they are more willing to invest in production equipment and laboratory reliability testing apparatus. These factories also have a distinct advantage over those in other countries: responsibility. “If they make a promise, they keep their promise.” Although the costs for these factories are increasing, they continue to be the first choice for major European and American manufacturers.

6. The Disadvantages of Taiwanese Water Purifier OEMs

- As the vast majority of manufacturers are OEMs for European and American brands, overall control of an order is not in their own hands, resulting in the risk of transfer due to small price differences.

- High OEM costs: An increasing number of manufacturing plants in emerging countries are also choosing to enter the OEM business. They benefit from lower prices, which can significantly impact orders placed with Taiwanese OEMs.

- Over 90% of Taiwan’s water purification industry manufacturers primarily focus on export orientation. This is due to the low population and domestic market in the country; the domestic demand market is nowhere near as large as that of mainland China (1.425 billion people), Russia (143.4 million people), India (1.412 billion people), Turkey (86.2 million people), and Vietnam (98.5 million people). With so many competitors, it is impossible for domestic demand to support every production plant in Taiwan.

- The shortage of workers and the unwillingness of young people in Taiwan to enter the manufacturing industry mean that OEMs often have orders but struggle to find technicians to fulfil their production needs.

- Issues such as the scarcity of land available for setting up factories have led to rising land prices, affecting the competitiveness of Taiwanese OEM manufacturers and indirectly resulting in smaller-scale production by OEM manufacturers.

7. List of Top 5 Trustworthy Water Purification Equipment OEMs in Taiwan for 2023 [Arranged by the English website of each company]

1.AQ & Q CO., LTD. (Aquatech)

www.aqq.com.tw

AQ & Q (Aquatech) was established in 1983. At the beginning of its operations, it primarily produced woodworking machinery. In 1993, it transitioned to developing and manufacturing pumps and RO water purification components for pure water machines. The founder, Mr. Zeng, was particularly persistent and demanding regarding quality from the outset. He spared no expense in purchasing an all-electric injection moulding machine made in West Germany to produce the components of the four-way valve, aiming to stabilise the quality of each product.One notable aspect of this factory is that it has applied for a considerable number of product certifications, including NSF, CE, RoHS, and UL.The company has consistently maintained a focus on OEM/ODM production. The founder has also successfully transferred the business to the second generation.

2.Dianapure International Co., Ltd.

https://www.diana-pure.com

Founded in 1997, the company has a factory located in Taichung City that covers an area of 700 ping (2,340 m²) and employs around 60 people. It specialises in the production and marketing of water dispensers, sparkling water machines, hydrogen machines/hydrogen water machines, electronic faucets, mechanical faucets, electrolytic water machines, and water purifiers and filters.The company primarily operates as an OEM for world-renowned brands, with products sold in over 30 countries globally. It holds dozens of domestic and international patents and has passed numerous stringent international safety regulations, such as EU CE, EU RoHS, China CCC 3C certification, US UL & ETL certification, Australia Watermark, Taiwan BSMI, water dispenser energy-saving first-level certification, CNS8088 lead-free certification, ISO 9001, and China Health License, among others.

3.Easywell Water Systems, Inc.

www.easywellwater.com

What distinguishes this factory from its peers is its responsible attitude:

(1) When I identify a quality issue, I will notify the customer each time, and initiate a recall of products in transit, as well as those already with the client.

(2) ISO-14001 International Environmental Protection Certification was obtained in 2001 (19 years ago), in order to take responsibility for the environment.

(3) The factory will be liable for compensation for any product quality issues or negligent services.

The company specialises in dechlorinating showers, water purifiers, and RO (reverse osmosis) water purifiers. It has developed, designed, moulded, and produced up to six models of dechlorinating showers. In fact, it can be said that the company and its factory are the most professional in Taiwan’s dechlorinating shower industry.

About 50% of Easywell’s revenue comes from RO reverse osmosis products, which are primarily supplied to assembly plants in Europe and the United States.

This OEM has also spared no effort in researching and developing key components of RO systems, with up to 80% of components being designed, plastic-injected, assembled, and tested in-house. Despite spending NT $10 million or more annually to develop a mould, there is minimal reliance on external sources. Key components are injected, processed, produced, assembled, and inspected in the company’s own factory, ensuring peace of mind and confidence for customers.

This company knows how to leverage its strengths, standing on the shoulders of giants when applying for and winning several national awards and government recognition:

- The 17th Rising Star Award (the first in the industry)

- Brand Star Award from the Ministry of Economic Affairs

- SME Innovation Research Award

- Small and Medium Business Administration Award

In order to enhance the factory’s quality and ensure that each shipment received by customers is consistent:

- Although a product laboratory was established at the inception of the company, in February 2020 an additional NT$ 17 million was invested in the construction of another laboratory and the purchase of testing instruments and equipment. This investment was made to further improve the reliability of the various instruments and products tested in the laboratory, including testing equipment and bacteria detection.

- The company obtained ISO-9001 international quality assurance certification in 1991, which it has maintained ever since. It utilises methods such as QCC (Quality Control Circles) and TQM (Total Quality Management) to ensure ever-increasing stability in product quality.

- The company has also acquired numerous certifications for its products:

- Several products (including gooseneck faucets and specialised refrigerator filters) have received NSF product certification: https://reurl.cc/yy5a8D

- Four products have been awarded the Provincial Water Mark by the Ministry of Economic Affairs

- It has received the Taiwan Excellence Award for five consecutive years

- A total of 54 products have passed CE safety certification

- The company holds 91 patents globally.